CPC6000FA Deburring Machine

Robust Power, Uncompromised Precision, Fully Automated

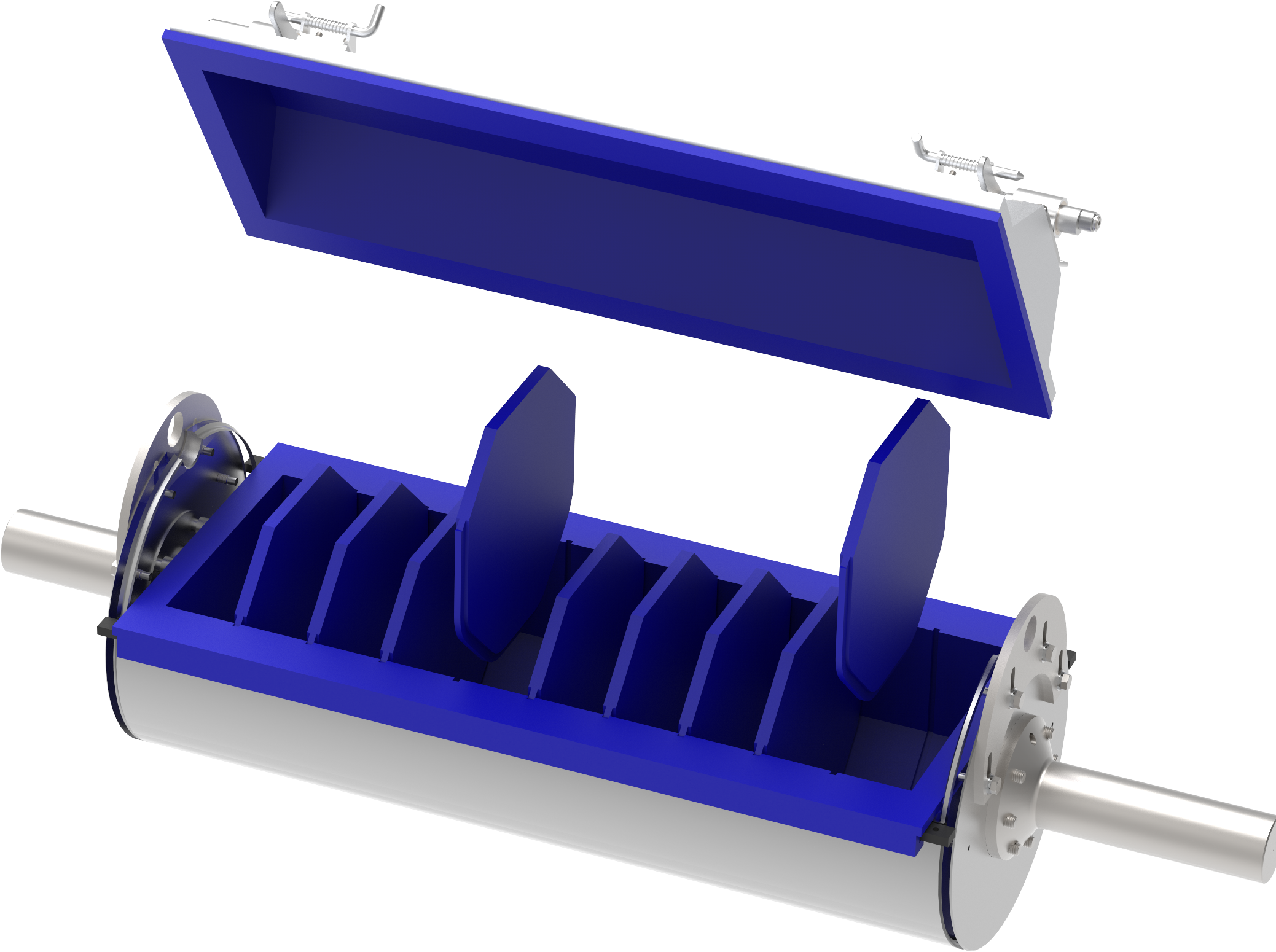

The CPC6000FA is the fully automated model of United's CPC6000 deburring machine. It combines the simple operation of United's other machines while offering unmatched power and full automation. Parts as long as 30" can be processed with ease and precision. Each barrel can be divided into as many as 10 compartments, providing the versatility to process a wide variety of parts. The CPC6000FA is equipped with our automated media and compound fill system as well as United's advanced media elevator making it easy for operators to run processes all day.

Features

The CPC6000FA is the CPC6000's fully automated counterpart. Its advanced media elevator and fill system offer unmatched automation among all deburring machines. It includes a lid storage system to minimize operator lifting and loading time. The CPC6000FA is perfect for large-scale continuous operations. The CPC6000FA comes standard with a PLC, touchscreen controls, and an internal rinse and separation system. Each urethane barrel can be divided into up to 10 compartments and can be adjusted to meet a myriad of deburring and mass finishing needs. The CPC6000 & CPC6000FA are ideal for high volume and heavy-duty processes.

The CPC6000FA’s media elevator, water, and liquid compound fill system bring full automation to the CPC6000. It is optimized for quick process turnaround and minimal downtime. It is similar to United's CPC4000FA deburring machine.

The drive system in the CPC6000 is powerful and robust. and is composed of heavy-duty chains to eliminate stretching. Power locks prevent slippage or premature wear on sprockets. United's drive system is durable and easy to maintain. All maintenance can be performed by removing a side panel with just 4 screws.

Barrels on the CPC6000 are longer and deeper than the CPC4000, offering 50% morecapacity and habing the spacer to process larger parts. The use of an injection-molded urethane liners allows the customer to replace barrel liners quickly with minimal down-time. Cradles can be fitted with dividable liners. These liners contain slots for 9 dividers which create up to 10 compartments within each barrel.

The CPC (Computerized Process Controller) is capable of storing a large amount of process information such as: types and amounts of media and compounds, maximum number of parts per barrel, loading instructions, and cycle time and turret RPM.

The CPC6000's automated rinse and separation system separates and rinses parts and media through the use of interchangeable stainless steel separation screens which can be ordered in different sizes and be easily changed. The CPC6000 eliminates the need to remove barrels from the machine to access parts and media.

An optional parts separation lid is available.

Touchscreen Controls

User-friendly touchscreen display.

Process storage capabilities.

Process countdown timer.

Safety

Two-handed jog operation.

Door lock prevents door from being opened while machine is running.

Emergency stop button.

Variable Speed

Up to 175RPM

Process versatility.

Gentle on delicate parts.

Barrel Liners

Divided option available, standard.

Easy relining - no need to disassemble machine.

Fully Integrated Motor Controls

Easy to operate.

Safe - operator has no access to line voltage.

Improved motor protection.

Removable Body Panels

Easy access for maintenance.

Replaceable panels, no need for bodywork or welding.

Easy cleaning.

Stainless Steel Construction

Prevents corrosion from moisture.

Equipment lasts longer.

Urethane Barrels

Greater traction increases energy transferred to the media.

Greater process efficiency.

Improved heat resistance.

Barrel Locks

No tools required to open barrel.

Increased operator convenience.

Reduced reloading time.

Warranty

Up to 3 years, determined by component type.

Complies with ANSI/NFPA 70 and NFPA 79 Codes UL Approved

Nationally accepted safety standards.

Trusted safeguards for operators and equipment.

Standardized design.

Specifications

Total Capacity

6 Cubic Feet | 168 Liters

Barrel Capacity

1.5 Cubic Feet x 4 Barrels

Barrel Dimensions

D 10” x W 30” (internal)

Machine Dimensions

D 80” x W 108” x H 128”

Max Capacity

10, 2½” Compartments per Barrel, 40 Total

User Interface

Touchscreen with Process Storage

Main Drive/Motor

25HP, Inverter-Controlled, Three-Phase

Turret Speed

0-175 RPM, Fully Adjustable

Operating Volume

~85 Decibels

Construction

304 Stainless Steel

Power Requirements

380VAC-480VAC, 50/60Hz, 3Ø, 30A UL certified

Water

Required.

Compressed Air

80-100psi

Dry Floor Compatible

Yes

Warranty

Up to 3 years, determined by component.

Options

Extra Barrel Liners

Separating Barrel Lid